Ammonia was used for refrigeration in 1876, for the first time in a vapor compression machine by Carl Von Linde.

Ammonia was used for refrigeration in 1876, for the first time in a vapor compression machine by Carl Von Linde.

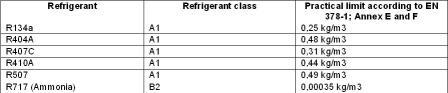

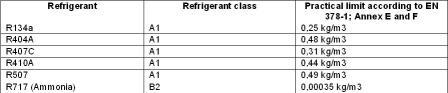

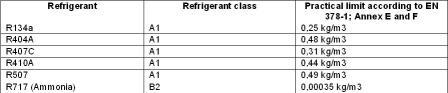

It is also the only refrigerant outside the halocarbons group. I just theoretically calculated two refrigerants of R22 and Ammonia … Ammonia Or Freon For Refrigeration? Chiller Basics: Understanding the Advantages and Drawbacks of Five Types of Chillers Chillers are the most common type of machines used for cooling large commercial spaces. Ammonia will benefit from any application having high refrigeration loads and low heating loads, as the efficiency of the cycle is much better. What happens if we use the same size heat exchangers for both refrigerants and then compare the energy use, ammonia would be better because the approach temperatures would be smaller. You can find the water-cooled chillers in the internal units. Ammonia Vs Freon? Other refrigerants like CO 2, SO 2 also were commonly used till 1920s. Ammonia offers a wealth of benefits for industrial refrigeration. I just theoretically calculated two refrigerants of R22 and Ammonia … The decision may be a quick one if ammonia is not permitted at the location or its use is inadvisable. Ammonia is safe for the environment; Ammonia based refrigeration systems cost less build and install The IPLV efficiency is 12 percent higher in an ammonia chiller. In this article we will be covering this topic to understand the basics of HVAC central plant. The ammonia-water system uses water as the absorber and ammonia as the refrigerant. Refrigeration & Mechanical Services provides solutions and products for any commercial refrigeration need. Perhaps, but the size of the ammonia chiller will be smaller than the R-22 chiller. Included in an information pack is a document that analyses the main advantages and disadvantages of the most widely used refrigerants in cold stores and food processing, namely R404A and R717 (NH3, ammonia), when employed in mechanical compression chiller systems. Absorption chillers are either lithium bromide-water (LiBr/H2O) or ammonia-water equipment. For each arena, the energy consumption of ammonia’s pumping and vent fans need to be compared to CO2’s loss of refrigeration cycle efficiency. Chiller Basics: Understanding the Advantages and Drawbacks of Five Types of Chillers Chillers are the most common type of machines used for cooling large commercial spaces. Purposes of Air Conditioner VS Chillers All chillers have powerful fans that help to cool its condenser coils. This is the most popular refrigerant used in chiller plants. The depicted exchangers are already available, whereas we need to buy a convenient refrigeration package. The Fernie arena recently reopened after installation of a new ice rink chiller that uses Opteon refrigerant. Ammonia or R717 is amongst the oldest of all the refrigerants and still used widely in the refrigeration applications. How does a Chiller, Cooling Tower and Air Handling Unit work together to provide air conditioning (HVAC) to a building. Refrigeration & Mechanical Services are capable of installing either type of chiller. The external units of a chiller include a cooling tower which helps to remove heat. All those who are involved in food preservation and industrial process plants know ammonia as refrigerant of choice due to its unmatched thermodynamic properties. - posted in Industrial Professionals: Dear all As per attached diagram, we in our plant intend to cool two streams of styrene monomer and 1,3 butadiene using a refrigeration package. This helps in recycling water to an external cooling method or a heated seat. Whether to choose an ammonia refrigerant or an alternative CFC refrigerant is an all too frequent debate. The ammonia chiller has a much better part-load efficiency. There are several types, and each type offers specific pros and cons based on the application, facility … Same for the condenser. Does that make it more efficient? State-of-the-art components for ammonia refrigeration. R717 Ammonia. Its chemical formula is NH3. There are several types, and each type offers specific pros and cons based on the application, facility … They account for less than 2% of large chiller shipments in North America, but are more commonly used in … The price per kg for R22 is about 2.5 times and R134a is about 7.0 times the price of ... smaller pipe sizes for a large system spread over a large area due to less drop in saturation temperature compared to Freon. Susan Wagoner, RAE Corp. ... “At higher temperatures, we were able to run a glycol chiller off of the ammonia system and use brine coils in the nut storage area. Absorption-cycle chillers typically use water and lithium bromide as the refrigerant and absor-bent, respectively, in larger sizes and ammonia and water in smaller sizes.

Ammonia was used for refrigeration in 1876, for the first time in a vapor compression machine by Carl Von Linde.

Ammonia was used for refrigeration in 1876, for the first time in a vapor compression machine by Carl Von Linde. Ammonia was used for refrigeration in 1876, for the first time in a vapor compression machine by Carl Von Linde.

Ammonia was used for refrigeration in 1876, for the first time in a vapor compression machine by Carl Von Linde.